The world's first affordable and scalable circular process to destruct asbestos fibres from cement and recover CO2 neutral raw materials

Asbeter's patented AC Minerals process is a mechanical-chemical process that generates high alkalinity for destructing the asbestos fibres. With this breakthrough technology, asbestos cement roofing sheets, pipes and insulation materials can be processed safely, resulting in a clean flow of calcium silicate and calcium carbonate as a circular building material as the end product. Asbeter is developing its flagship plant in Moerdijk, the Netherlands and wants to complete the basic engineering in the coming months. The Final Investment Decision for the construction of the plant is foreseen for Q4 2025.

From problem to solution

The Netherlands wants to be a circular economy by 2050. Raw materials must be used and reused efficiently, without harmful emissions to the environment. This is not an easy task for some raw materials, such as with asbestos-containing materials such as asbestos-cement roofs. Asbestos fibers must be completely destroyed in a safe manner in order to reuse the cement.

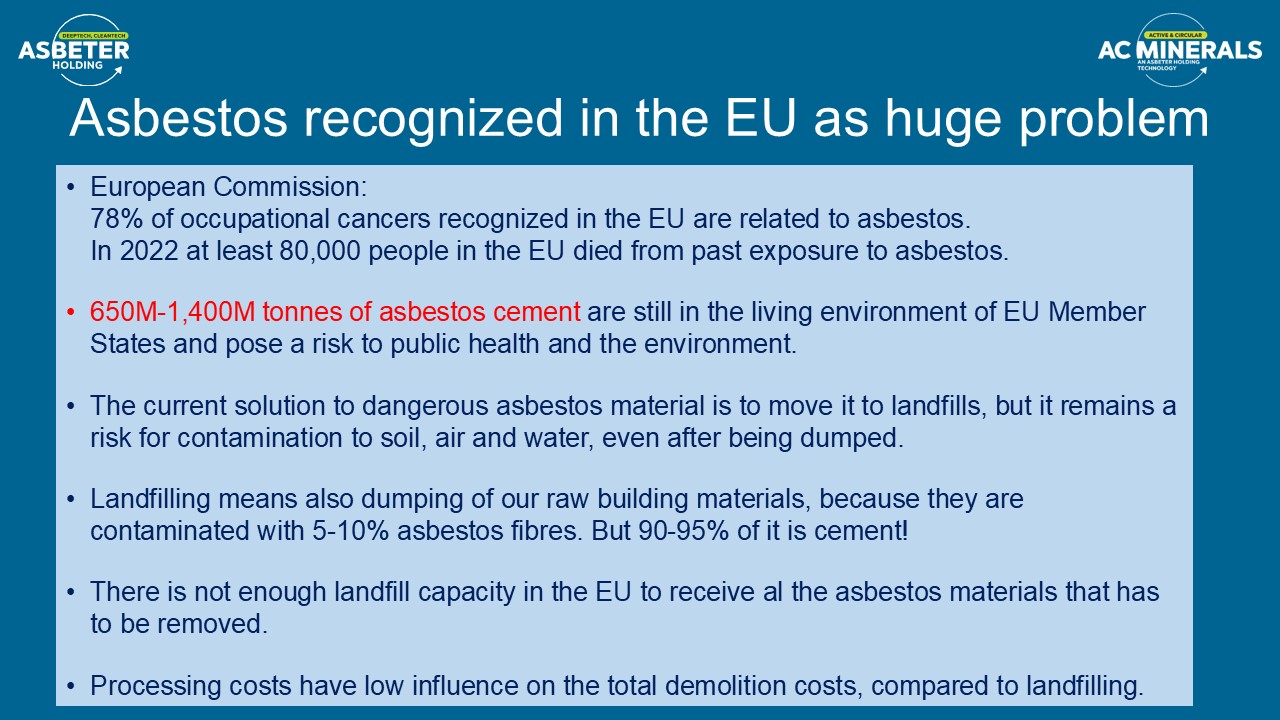

Millions of tons of asbestos cement are still in our living environment. When disposed of, they end up in landfill because they are contaminated with 5-15% asbestos fibres, where they continue to pose a risk to public health and the environment. The remaining 85-95% of cement also disappears underground with the asbestos fibers. The shortage of landfill capacity is a problem for asbestos removal in many countries.

In addition, the European Commission has determined that 78% of occupational cancers in the EU Member States are related to asbestos. There is currently no environmentally friendly, safe and affordable process to solve the asbestos problem other than landfill. But landfills are limited. Landfill costs are artificially low or high (€150 to >€450/tonne asbestos waste in Europe) and landfill sites are limited. Alternative processing methods are still in their infancy or have stopped, such as plasma technology, thermal recycling and acid technology. The biggest problem is that they are very expensive, environmentally unfriendly and do not guarantee an asbestos-free final material.

Our scale-up company Asbeter, founded in 2018 in the Netherlands, has developed the AC Minerals process in 2022.

This is a unique and holistic solution to process asbestos cement effectively and safely by destructing the asbestos fibers and recovering 100% raw materials: calcium silicate and calcium carbonate.

Asbeter will build and operate the first commercial installation in the Netherlands to process asbestos cement and provide a safe and sustainable solution for asbestos fibers by bringing CO2-neutral raw materials back onto the market.

Processing 75,000 tons of asbestos cement roofing sheets, pipes and insulation material, our production capacity can deliver up to 124,000 tons of calcium silicate hydrate (CSH) slurry at 50% dry matter per year. Our activities start in the Netherlands and we expect to grow with international licenses from 2027.